Always one step forward

In the laboratory, we test both prototypes of our own development and the products of competitors. Once the components for optimal operation of appliances have been defined and harmonized, they are placed in the space of the appliance in the development department. In doing so, we take into account laboratory instructions, design, possibility of production and safety requirements.

We always strive to be one step ahead of time, striving for the best

possible efficiency and safety of systems.

How does a new solution come about?

Based on extensive experience, careful analysis of competitors and improvement of solutions of previous generations, the concept of a new product is born. With a series of simulations, we select the most suitable components to achieve the best results. Often, the specific requirement of a particular market leads to a completely new solution. For example, a buyer in Belgium wanted a product tailored to the needs of district low-temperature heating – and a heat pump for sanitary water Booster was created!

What do we work with?

We use state-of-the-art software: SAP, CREO, Windchill PLM and LabVIEW. With LabVIEW, we perform simulations of the operation of the appliance. Other simulations are carried out in cooperation with external partners. We simulate plastic injection moulding, air flows in the room and vibration of components (due to the potential impact on noise).

Tiki for others

When a manufacturer makes an appliance as a customer under his brand as a result of its development, this is called OEM (Original Equipment Manufacturer). Appliances have exactly the same characteristics as original appliances. Tiki manufactures devices for about twenty such customers around the world.

What do we do in the laboratory?

We develop prototypes and new products, testing their effectiveness and durability. For this purpose, we test many new technologies, perform thermodynamic calculations and simulations, and develop control algorithms.

We design complete heating systems and offer support to production and service. We carefully monitor European ecological standards and legislation. We also provide testing services for external companies.

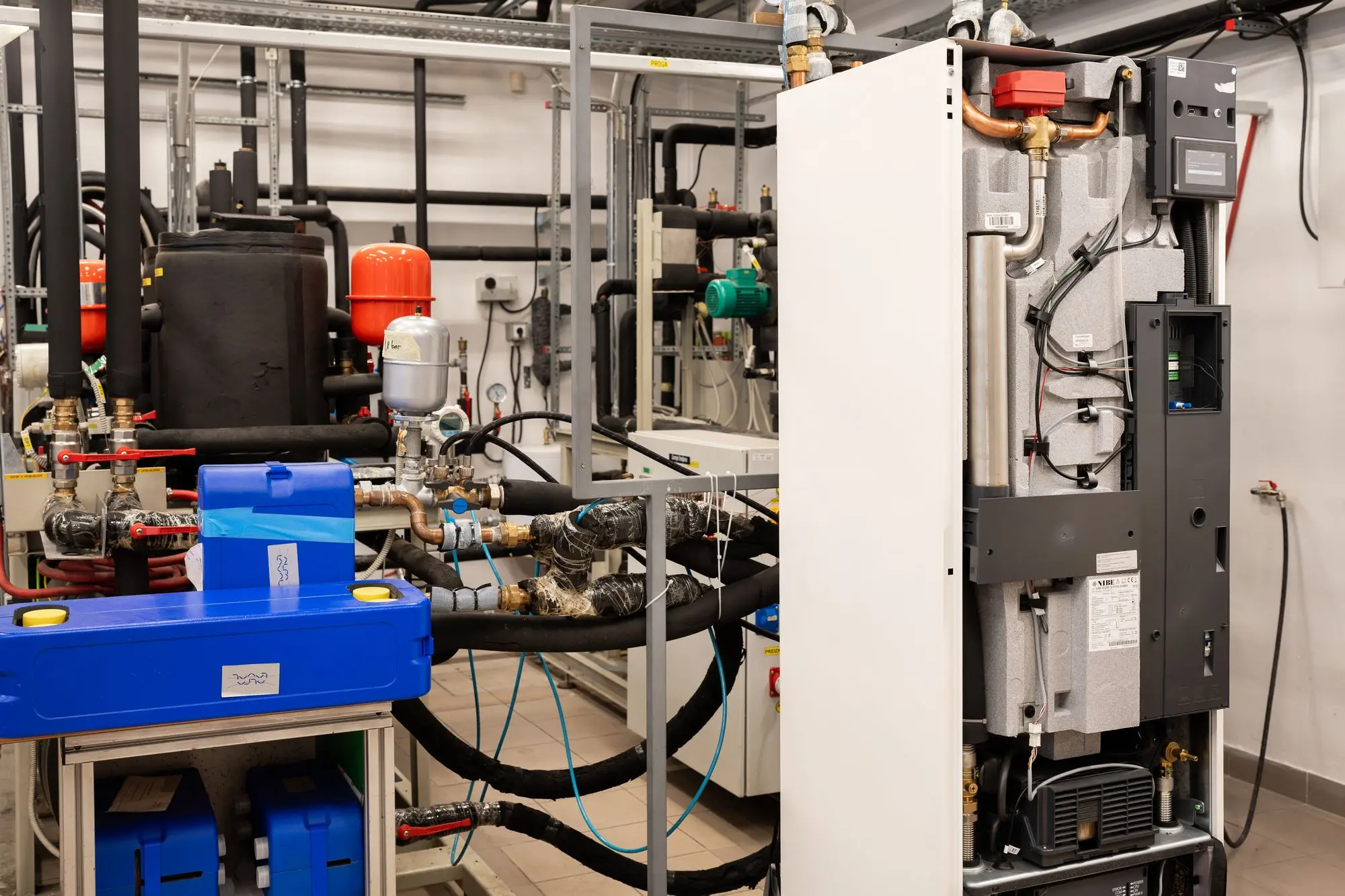

Tiki's laboratory tests the capabilities of its own prototypes and products of the competition.

How do we design products?

Already in the product design phase, e.g. heat pumps, there is a dynamic interaction between the systems. We anticipate optimal installation and prescribe installation parameters that ensure planned and laboratory-verified performance. With the development of the regulation algorithm, we strive for the user-friendly start-up of the device (plug and play). The findings of the laboratory also contribute to the production of high-quality installation and user instructions.

Who and what do we work with?

On approximately 500 m2, six highly qualified experts operate climate chambers, measuring lines and numerous measuring systems and instruments. Among the state-of-the-art equipment, you can find a training ground with two calorimeters for testing water-water or brine-water heating heat pumps, as well as training grounds for testing the mechanical properties of boilers, heat losses of high-liter water heaters, and the development of control algorithms in the LabView environment.

Among the chambers, the most demanding are the test chamber with a calorimeter for air-to-water heating heat pumps, three test chambers for sanitary heat pumps and two test chambers for electric water heaters.

What is prototyping?

Based on the developed concept of the new product, we order components from various suppliers, and in the workshop we assemble a functional prototype. This is followed by the first tests and analysis of the results, during which we identify possible deviations from the planned capacities. Based on these analyses, we optimize the prototype to serve us for confirmation and creation of product information.

The laboratory extends all the way to service

We offer maximum support to service technicians in solving problems in the field. Since we thoroughly get to know the products during testing, we can infer from the operating parameters what deviation or malfunction occurred – and advise the optimal solution.

In the event that the problem cannot be resolved in the field, we connect the product to the measuring base and by monitoring a large number of parameters, we detect the cause of the malfunction. We also help with the launch of specific configurations of heating systems.